Técnicas de motivación empresarial en la industria automotriz para evitar los siete desperdicios

Muda, Mura, Muri Muda, Mura, and Muri are terms often used together in the Toyota Production System (and called the Three Ms) that collectively describe wasteful practices to be eliminated. An Introduction to Muda, Mura, and Muri Watch on Muda Any activity that consumes resources without creating value for the customer.

Los 8 desperdicios en la filosofía Lean Construction Cursos online

7 Wastes Lean will remove or reduce Waste or Non-Value adding steps in our processes. While waste removal should not be the focus of any lean initiative it will certainly be something that you achieve whilst seeking to implement the principles of lean manufacturing.

¿Qué es el kaizen? Principios, beneficios y aplicaciones en la empresa

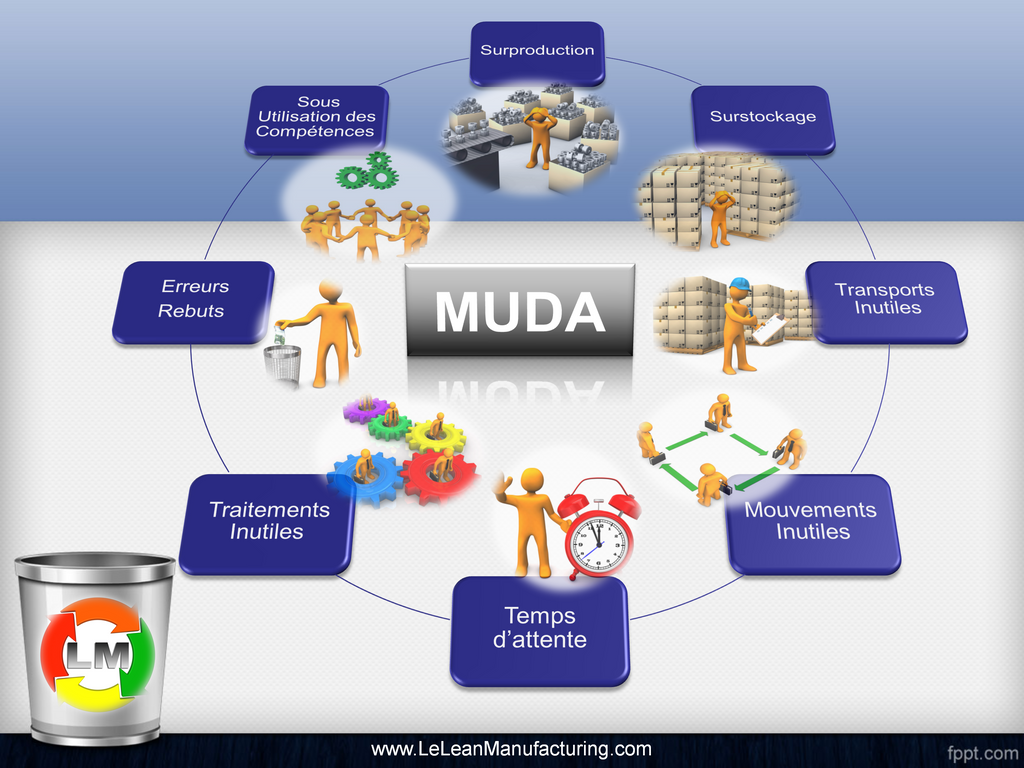

Toyota divides Muda into seven resources that are frequently wasted: 1) Transportation — a cost that adds no value to the product but increases the risk of a product being damaged, lost or delayed; 2) Inventory — a capital outlay that if not processed immediately produces no income; 3) Motion — any damage inflicted through the production process.

The Seven Muda (Seven Wastes) Lean Six Sigma Complete Course. YouTube

The 7 wastes constitute 'muda' and were originally articulated by Toyota's Chief Engineer, Taiichi Ohno. They are a core part of the Toyota Production System, now more widely known as Lean Production, or Lean Manufacturing. We recently looked at another Lean Production tool, Kanban.

Think Lean, Think in Kaizen 7 MUDAS

Global Lean Leader Opex Director. Many people ask me about examples of Mudas (wastes) on 3 main categories, Manufacturing , Office and Supply Chain; for that reason I always share the next table.

7 mudas Kaizen, Mudar

The Toyota Production System, the precursor of Lean Manufacturing and Kanban, identified 7 Mudas or Wastes: Transportation, Inventory, Motion, Waiting, Overproduction, Overprocessing, and Defects. As the system has evolved and been adopted in knowledge work sectors, an 8th Muda has been added to the list: the waste of human potential.

7 Mudas Kaizen

Based on his observations and deep analysis, he categorized the 7 types of waste (7 Mudas), which later became a popular practice for cost reduction and optimizing resources. What Is Muda (Lean Waste)? Waste in Lean is any activity that consumes resources but brings no value to the end customer.

Kaizen on waste elimination

Muda, The Seven Wastes Muda is any activity or process that does not add value; a physical waste of your time, resources and ultimately your money. These wastes were categorized by Taiichi Ohno within the Toyota production system, they are; Transport; the movement of product between operations, and locations.

May this be the Kaizen week! King DMC

7 MUDA "Waste!" We Help Operations Managers to Conceive and Actualize Their Industrial Visions Based on the Lean Manufacturing Culture Open menu About Us The 10 good reasons to choose Lean University Our References Lean Trainings Our Training Sessions Lean Trainings calendar Dojo Company Visits Japan Study Tour Custom training Lean Trainings Paths

7 Wastes The Seven Muda ToughNickel

The seven wastes of Lean Manufacturing are what we are aiming to remove from our processes by removing the causes of Mura and Muri as well as tackling Muda directly. But what exactly are the seven wastes of Lean Manufacturing (or 7 Mudas)? The Seven Wastes of Lean Manufacturing are; Transport Inventory Motion Waiting Over-Processing Overproduction

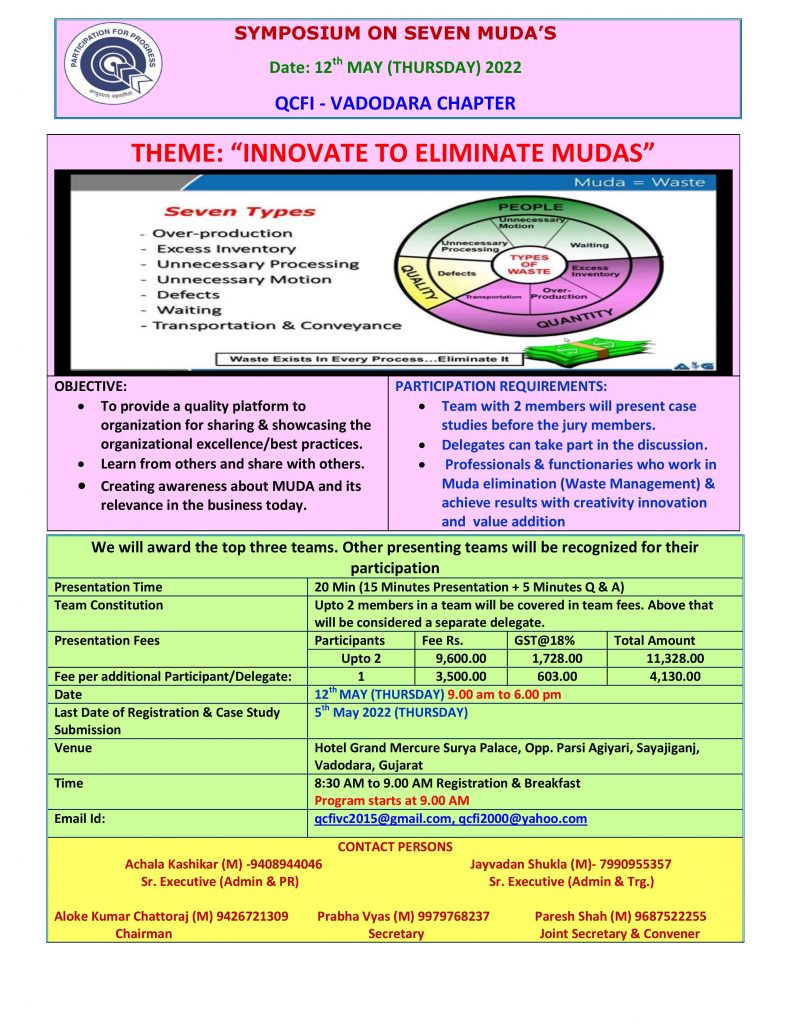

Flyer 7 Mudas QCFI Quality Circle LQC 5S Kaizen Total Quality Management Training

The 7 Wastes of Muda are as follows: Overproduction: Producing more than is needed. Waiting: Waiting for materials, instructions or processes. Transportation: Moving products, materials or people unnecessarily. Over -processing: Using too much processing time or resources. Inventory: Having too much inventory on hand.

7 Wastes of Lean How to Optimize Resources Lean manufacturing, Lean project, Management

These wastes can come in many forms and are commonly known as the 7 waste or 7 Mudas,. Kaizen: Kaizen is a Japanese word that means "continuous improvement". It's a strategy where employees at all levels of a company work together proactively to achieve regular, incremental improvements to the manufacturing process..

24+ Ide Terkini 7 Mudas Lean Manufacturing

WHAT IS MUDA - 7 WASTES IN LEAN WHAT IS MUDA Learn all about Muda (7 wastes of lean) with examples from manufacturing and service industry. It is very easy to remember all the 7 wastes by just remembering TIMWOOD. MUDA is a Japanese word, which means "Waste". Muda are non value added (NVA) activities in the workplace.

Kaizen Wheel Kaizen, Classroom organisation, Social science

What are the 7 MUDA (7 WASTES)? by Dante Garcia on June 14, 2019 One Comment Upkaizen School Changing business for the better Recent Cases What they say Laverne Angela Gadiah Thank you for a very clear, easy to follow and concise course. It was informative and definitely on point. Cristyn Narciso

INNOVACIÓN Y PRODUCTIVIDAD Conferencia de Masaaki Imai

What are the 7 Mudas? Muda isn't just about the typical waste, most people would have thought of garbage. That's not wrong but it's not all that there is. In TPS and lean management, muda is subdivided in seven categories. Originally created by the chief engineer in Toyota the seven wastes (commonly abbreviated to TIMWOOD) are: 1. Inventory

20+ Konsep Top Les 7 Muda

The Waste of Waiting . Waiting is one of the seven wastes of lean manufacturing (or 7 mudas), it is the act of doing nothing or working slowly whilst waiting for a previous step in the process. How many times have you seen operators stood waiting for a previous operation, a delivery of products to arrive or just slowly working so as not to highlight that they have run out of materials.